A Chat With Darrell Smith

| by Mark Wicks | 11 February 2017 |

| Tweet | |

I bumped into Rotax’s Darrell Smith at the Todd Rd Pro Tour round last month. Darrell was in Australia for Christmas and New Year and had overseen some Mojo tyre testing at the venue prior to the race meeting.

As elder karters do, we started talking about ‘the good old days’, reminiscing in the past and remembering some pretty major highlights, both of us having taken a Masters victory at Rotax MAX Challenge Grand Finals. This was back in the day when the qualified participants brought their own karts to the event.

“Actually, it was pretty special for us” Darrell said, “because we were able to do it driving Australian made chassis” (both won using DPE Arrow).

Darrell was the first driver to win a ‘Masters’ classification at a Rotax World Final (the 2001 Grand Finals that were held in Malaysia, 2002) and was 4th outright in Senior MAX.

Above: All three of Australia's Rotax Grand Final Masters winners were at Pro Tour in January (left to right) Lee Mitchener - DD2 Masters, 2016 Grand Finals in Italy, Mark Wicks - MAX Masters, 2003 Grand Finals in Egypt, and Darrell Smith - MAX Masters, 2001 Grand Finals in Malaysia (pic - Jen Wade)

The following year in South Africa, he had all but defended his Masters title, and was even threatening an outright podium once again, when his fuel line came off.

“That was my race” he reflects, re-living the agony of a lost title all those years ago.

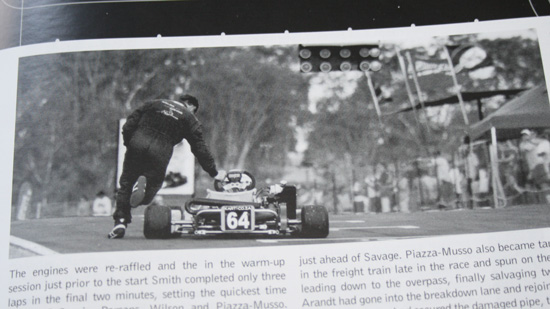

But that let-down was also the catalyst that gave him the opportunity to join Rotax. To the applause of onlookers, Smith started pushing his kart to complete the final lap.

“I pushed the kart to the line to finish the race. If I’d spat the dummy and thrown my helmet to the ground and stormed off, I’m sure the offer (from Rotax) would not have come. You need a level head - you never know who’s watching.”

We agreed that the Grand Finals today are totally different to what they were in the early years.

“But you still can’t take it away from the fact you went there, learned what you needed to do and got the job done.

“Anyone who qualifies for Australia and gets over there has got a shot at it. But they need to be smart and learn the process of what goes on at these events.

“Look at Lee, and you and me and Ben George. There’s only a few of us who have actually done it (awarded a win).”

Above: The one that got away. Smith pushes his kart to the finish line in South Africa (pic - KartOz Magazine #72)

KSN - So, what was with this tyre testing you mentioned earlier?

DS - This Pro Tour round is the first race, worldwide, on the new D3-plus 2017 spec tyre. We had issues with them at the 2016 Grand Finals (excessive wear), which we traced back to a problem with a setting in the manufacturing process. To be honest, we were lucky it rained (at the Grand Finals) and had to use the wets for some races.

KSN - Lee Mitchener told me there was talk at the drivers’ briefing (after the heats) that everyone would get new tyres for the DD2 Masters final, but he and a few others objected. Lee said the rules stated one set for the event, so he and his team planned to conserve tyres in the heats knowing they would need them in the final.

DS - That’s exactly right. We were looking at giving all the qualified drivers for the final a new set of tyres. It was something that was being considered, but it would not have been fair to those who had driven to the tyre and held back in the heats.

But once we corrected the setting on the machine in manufacturing, we were back to what was the original plan for that tyre. The Grand Final tyre last year was supposed to be what we are running here today. And so far, it’s proven really good. We’ve tested at three tracks and been very happy. Rotax is waiting for me to report the feedback tonight.

We’ve also put Juniors back to the D2 to get the lap times to be a more logical spread from Juniors to Seniors.

KSN - Rotax has just announced the chassis partners for the 2017 Grand Finals, and it’s the same as last year. How are these manufacturers selected?

DS - There is a tender system in place and there are a number of areas where we stipulate what’s needed. For example, in addition to all the karts that the drivers will race, there must be another 5 complete karts ready to go and the manufacturers will have maybe another 10 bare frames to use if need be. It’s a big effort by the manufacturers, but they get enormous publicity from it. Those that supplied last year (Birel ART, IP Karting and Sodi) all wanted in again.

We provide the engines to the manufacturers beforehand (they are installed on chassis prior to the event) and they basically have all their karts sold prior to the event, to be distributed afterwards through their dealer network. Every engine is accounted for in the system, so if karts go into a country with engines on them, the local distributor is compensated for those engines they didn’t get to sell.

KSN – Each year we see the iconic photos of all the karts lined up on track for the famous kart raffle. But there’s a lot of work after the event that we don’t hear about. (Drivers get to use the kart at the Grand Finals, but any damage must be paid for and karts returned in a basically as-new condition.)

DS - The karts have to be returned to us spotless, in good condition and with all of the original components.

They are all new chassis at the start of the event, and at the end they all get checked and measured on a jig. If a driver bends a frame, they have to buy it back. If it’s under 4mm difference, we’ll accept that, but anything 4mm and over, it needs to be replaced.

As I mentioned, we check the chassis, but also the clutch, make sure the fuel and air filters are still there, spark plug is ok, all the exhaust springs are still intact and even the sticker kits are unmarked. Everything is double checked. If a radiator is damaged, they have to buy a new one.

KSN – You have a new Arai helmet coming with a special, and appropriate, ‘test pattern’ livery, and you still do a lot of driving. But do you ever get the urge to compete and race again?

DS - The last time I raced was the 24-hour kart race at LeMans in 2006 - and that’s something I’d be interested in again this year. It would be great to have a team of Australian drivers, but it’s probably getting a bit late to put all that together.

It’s the type of event that appeals to me because you need a completely different mindset. With all the durability testing we do I think it would be appealing. I can do about 25,000 kilometres per year.

KSN - 25,000?! What’s that involve?

DS - Durability testing, evaluating parts that affect performance, problem solving and also distributor training. Sometimes we get a customer or distributor with a problem and we have to go to the track and try and replicate it and work out what the problem is and a solution. And with distributor training, while it’s mostly technical training, they often want tips with driver training on the track as well.

KSN – Driver training is something you’ve been doing for a long time now. In fact, you were probably the pioneer of professional kart driver training in this country.

DS - Yeah, I was the first CAMS accredited driver trainer for karting. I think we were also the first to take karting kids to the Australian Institute of Sport. After learning about diet and eating healthy, I recall some then sneaking out to McDonald’s!

Above: Darrell with Mini MAX driver

Cody Maynes-Rutty at Todd Rd Pro Tour (pic - KartSportNews)

KSN - Has Rotax ever looked at running the MAX Challenge Grand Finals in Australia?

Yes, always looking. But there is not a track here that could run the event.

The time frame, Australia is perfect with the weather and so on, but with the number of people… there’s around 400 drivers so with pit crew and family, there’s around two to three thousand people moving in and out every day. There needs to be infrastructure in place like accommodation and hire cars for that number of people. While here in Melbourne that could probably work, it’s a struggle for a lot of tracks in other countries we look at.

But the event would not fit in this track (at Todd Rd). I don’t know of a track in this country that has a large enough sealed pit area to take our big tents that we put everyone under.

KSN - Are the engines dyno tested for parity before the Grand Finals?

DS - No. I need to explain the process.

The recreational engines are manufactured in Austria, and it used to be the same people who built all the different engines. We would have to book into production, say, 300 kart engines this month, then book another 600 into the build schedule the next month. But with that, we had for example engines with slightly different squish coming from one batch to another. While that is fine for a recreational engine, it’s not for competitive competition.

But now we have specific engine builders for the kart engines. These engines are for racing and have to be built to much finer tolerances than recreational engines. With the new pistons and clearances we build to, there is no need for a run-in. I personally still like to give them 10 to 15 minutes, but you can run them hard straight away, so there’s no need to put them on the dyno before the event.

And due to all of this, from a technical perspective, last year’s Grand Finals (with the Evo engines) was definitely the best yet.

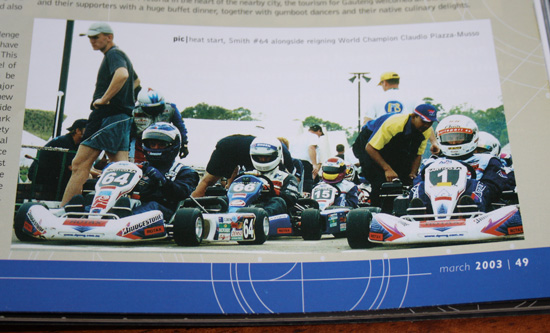

Above: Darrell #64 on the front row for a heat race at the 2002 Grand Finals in South Africa, alongside defending Senior MAX World Champion Claudio Piazza-Musso (pic - KartOz Magazine #72)

KSN - Do you get many people complaining they think they’ve got a dud engine at the Grand Finals?

DS - You still get one or two. For example, last year there was one junior and his dad who thought their engine wasn’t much good. We checked it over and it was all ok, so then we looked at his data. After going through that and pointing a few things out with his driving we got him up to speed.

We did have some top-end, as in higher in the RPM, issues with DD2s, so we adjusted the plate for the reed block and fixed that.

KSN - Speaking of DD2, that started with Rotax’s own one-make RM1 chassis. How many of those were built?

DS - Maybe around 500 of them? Opening DD2 up to the market was the best thing we did. If we’d stayed with the RM1 concept I think we would have killed it (DD2).

KSN - What of the future?

DS – We want to keep it stable and not change too many things.

- The next round of the Australian Rotax Pro Tour is at Bolivar, South Australia, on March 10 to 12. For more information, see rotax.com.au

- Lee Mitchener interview, after winning the 2016 DD2 Masters World Title, is HERE.